This content was reviewed for accuracy on 21/08/2023

How often do you think about supplier packaging? You probably don’t right? You likely only think about when you’re shipping goods out.

When you’re buying goods online, you don’t call the shop up and tell them you want your vase bubble-wrapped in a box, do you? Of course not – you assume that they’ll package your goods correctly to get them safe to you. If they don’t and your goods arrive damaged, you’d expect a full refund.

If that’s how it usually works when you buy a product on Amazon or through an online shop, we understand why you wouldn’t think any differently when you are importing from overseas.

Is that the correct way to think? No – but that’s why we’re here. Read through the rest of this post and let us clear everything up…

How Supplier Goods Are Packaged

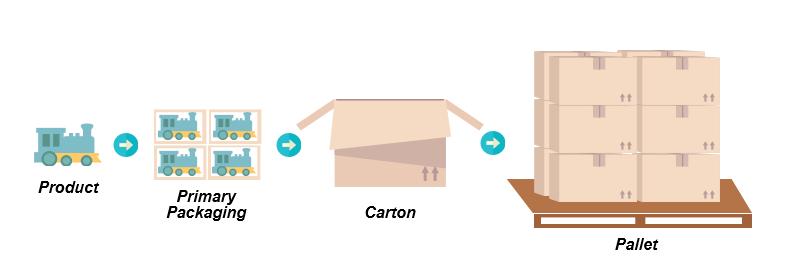

When we’re talking about packaging your goods, we’re referring to how the supplier packages your goods for their journey.

Your supplier will generally load your goods into cartons and sometimes place these cartons onto pallets to be shipped. It’s important that the packaging used is fit for the journey that the shipment will undertake.

If you’re returning the vase you borrowed from Mrs Smith over the road, it wouldn’t need to be packaged as well as if you’re sending it in the post. If you’re shipping 100 vases from the other side of the world in a container with lots of other people’s goods then you have to be even more thorough with the packaging.

This is how your goods would typically be packaged:

Is Packaging Up To My Supplier?

This depends…

Yes in the sense that your supplier is the one physically packaging your goods and taking care of all those costs – you don’t need to concern yourself with the packaging.

No in the sense that you should certainly take an interest. Ensuring that your supplier packages your goods in a suitable way for transportation is very important, especially if you’re paying to insure the shipment. This means that, if you don’t follow up with your supplier and your goods end up being damaged due to the packaging being substandard, you may not be covered.

Here’s what the small print in the insurance policy will probably say about it:

“…In no case shall the insurance cover loss, damage or expense caused by insufficiency or unsuitability of packing or preparation of the subject matter insured to withstand the ordinary incidents of the insured transit where such packing or preparation is carried out by the Assured or their employees or prior to the attachment of this insurance…”

Ouch!

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Cartons

When you think about it, it’s pretty obvious why it’s important for your goods to be packaged well – they go through a lot. You might not think about how many hands touch your goods and how much they’re jostled around. The cartons are loaded onto a truck, unloaded from the truck, loaded into a container, unloaded from the container etc. etc…

However, the true danger that often slips under the radar is gravity. When your goods are loaded onto a pallet, they’re all placed on top of each other – so your bottom boxes are feeling the weight of your other boxes (and maybe one or two of someone else’s).

When your goods are being packed into cartons, you need to be more careful than you may think. The way that these individual cartons are packaged is crucial to the end result. The secret formula to well-packaged goods that survive sea freight:

- Tightly packed, full boxes. There should be no free space – and where there is, there should be padding. This ensures that your box is strong and won’t end up crushed.

These individual cartons fit almost perfectly into the master carton. If they didn’t, additional packaging will be required to fill the space.

As you can see, these products are well packed within this box. If there’s space on any side of the smaller compartments, polystyrene could be used to fill the gap. The reasoning for not wanting space within the box is simple – free space means crushed cartons.

- Tip – if there is free space, take the opportunity to get some extra protection in.

Without the extra padding, there would’ve been a lot of empty space in this carton, & cause the products to move around. The extra protection ensures the goods are safe.

- Solid products are easier to pack. A lot of soft products release “fresh air” as other goods press down on them throughout the transit and can “settle in transit”.

Gravity wins – make sure your boxes form a solid base, or they may be crushed.

This can end up with a crushed carton. Think about Weetabix vs Corn Flakes. The Corn Flake box always looks half full when you open it with all the flakes at the bottom and air at the top whereas the Weetabix stays just the way it was packed due to little extra air being in the box! Suddenly, I feel hungry… anyway…

- You want to make sure that there is no air left in these cartons – air is what causes the cardboard to give up and end up folding under pressure.

If your supplier doesn’t package your goods well enough, there can be serious issues. If your boxes are too full, they can burst open and if they aren’t full enough they could collapse.

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Pallets

Pallets are the wooden slabs that your cartons are packaged onto. Not all suppliers use these as they have to be fumigated* and are less space-efficient than loose cartons. On the other hand, pallets are a much safer way and an easier way to transport and handle your goods. (This is because forklifts can be used with pallets instead of people having to manually move the cartons.)

*fumigation is required to treat the pallets before they enter the UK to avoid any parasites crossing the border.

If your goods are fragile, it’s a good idea to ensure that your supplier packs your goods onto pallets for their optimum protection.

As with cartons, there are a few things you can ask your supplier to do to make sure that your goods are packed onto pallets as safely as possible. It may seem like we’re nit-picking – but remember that any damage due to insufficient packaging will not be compensated. Insurance companies have a tight grip on their wallets, so protect yours!

- Shrink-wrap the goods onto the pallet.

This is a well-wrapped pallet; the boxes are well stacked and shrink wrapped to ensure they don’t fall out of place

- Stack the boxes properly. This means making sure that the boxes aren’t hanging over the side of the pallet, that the weight will be distributed evenly and that your goods are stable. It’s like high-stakes Jenga.

This is a well stacked pallet, the cartons over-lap so the weight is evenly distributed.

Not all goods need to be palletised, but it can be a real help to have goods on pallets while they’re being transported – especially when transporting fragile goods.

Whilst we’re on the topic of pallets and cartons, you might also find our post about pallets vs loose cartons helpful!

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

Save

- Shrink-wrap the goods onto the pallet.

Packaging Crates

If you have extremely precious cargo, however, you may want to forgo the pallets and opt for something even better – a crate.

A crate is the safest – but most expensive – way to package your goods. It practically ensures their safety but has to be custom made, which adds to the price.

Crates are specially built for your cargo and are the safest form of packaging that there is. Often built of wood, they’re commonly used for transporting machinery. One of the drawbacks of crating is the same issue that suppliers can run into when packaging goods on pallets – exporting wood needs fumigation.

There are regulations when it comes to exporting wood. These include treating the wood with necessary chemicals and fumigating it to ensure that any dangerous organisms are destroyed. All of this adds on extra work and cost for the supplier, who sometimes may be unenthusiastic about the prospect.

SaveSave

Save

Save

Save

Save

Contact Shippo About Supplier Packaging For More Info

If you want any more information about supplier packaging, or just have a few questions, feel free to contact us! We’ll be happy to help!

If you enjoyed this post or found it helpful, make sure to share and pass the information along – and remember the information we shared so that you aren’t caught out!

We have just imported a container from China for the first time with Shippo. We were nervous about the process involved but Phoebe at Shippo was very helpful and the website is full of useful information. Delivery was done swiftly after arrival of the container and at the allocated time.Annie O ConnorMore Posts You May Like

How To Prepare For An LCL Shipment

If you’re using LCL shipping to import your goods from overseas, then you’ll need to know what to expect and what your obligations and responsibilities

Compare LCL Shipping Rates & Save: Find the Best Price for Your China-UK Shipment

When importing goods from China to the UK, you want to be sure that you’re getting a good deal. Sea freight rates are dependent on

Is LCL Shipping The Fastest Way To Import From China?

If you’re looking to import goods from China, you’ll probably be wondering what the fastest shipping method is. In this blog, we’re looking at the